An introduction to ESD Flooring

Technological advancement from the late 18th century has undergone perpetual growth. Today, we are surrounded by a world of engineering marvels. Every innovation was once an experiment, and every experiment had its repercussions. Machines have grown from occupying an entire room to fitting into the palm of our hands. Consequently, over the years, repercussions of various magnitudes from acute damages to fatal accidents. Throughout the years, engineers have worked to suppress and extinguish the factors contributing to these unfortunate accidents. One such factor is static discharge.

Static electricity is generated as a result of friction, the most prominent force in manufacturing industries. Static charges have a tremendous impact on electronic components. These charges, if left uncontrolled, can increase to a potential of 40,000 volts. Hence protection of the workspace is necessary. Over the years, many technologies were incorporated into different materials which showed various results.

The three main technologies used are mentioned below:

- Anti-static flooring.

- Chopped fiber Electro Static Discharge (ESD) flooring.

- Nanotechnology infused ESD flooring.

The anti-static method employs materials exhibiting a resistance in the range of 109 – 1012. This type of flooring is made up of a material that does not generate static. Although, it is not capable of dissipating charges which arise due to other factors. It is not a popular choice as static is built due to various phenomena in an industry. Like the movement of plastic parts, metal garbage can being opened and closed often, conveyor belts in motion, rotating components, etc. Anti-static flooring is not chosen widely among industries as a result of this.

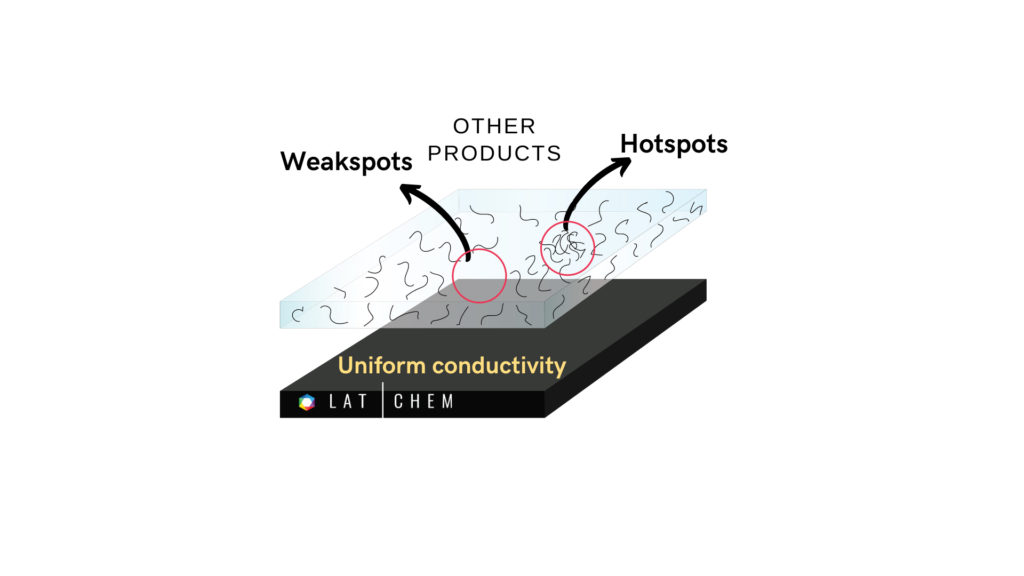

As anti-static flooring failed to dissipate excessive charges, Electro Static Dissipative (ESD) flooring was developed. This system consisted of conductive elements mixed in the flooring compound, be it tile or chemical. The widely used element even today is chopped fiber. These are thin black strands of carbon resembling pieces of thread. This layer is connected to a ground wire which transports all excessive charges from the conductive chopped fibers into the ground, ensuring protected work zones. Sounds ideal until you take a close look into it.

These chopped fibers are mixed manually by laborers making it impossible to be uniformly distributed, resulting in weak spots and hotspots. This is why no flooring applied using this method has ever tested to remain within the conductive range, thereby threatening the safety of the facility.

In Lat|Chem’s state of the art technology, we infuse nanomaterials into the flooring chemicals. Nanomaterials being 9 times smaller than bulk-sized carbon which guarantees thorough dissipation on a minute scale filling every inch of the system. These conductive elements are pre-mixed, unlike fibers which, not only makes them easy to use but also to reapply. Nanomaterials show different characteristics than its bulk materials; here, it strengthens the chemical resistance of the flooring system. Our flooring not only adheres to the global ESD standards of ANSI S20.20, ASTM F150, IEC 61340 but are also LEED compliant.

The safety of the unit is influenced by the choice of flooring technology. Latern offers the most advanced yet achievable solution with absolutely no other brand to contest with.

Ensuring static-safe industries since 2016.

Stay safe with Latern!