Revolutionizing ESD Flooring for a Multi-Billion Dollar Electronic Manufacturing Services Company

A multi-billion dollar electronic manufacturing services (EMS) company, specializing in mobile devices,5G modems, and components for battery manufacturing and electric vehicles, faced significant challenges with their existing ESD (Electrostatic Discharge) flooring. The company initially opted for ESD PVC tiles to meet the stringent requirements for ESD protection necessary to pass ASTM F150,ANSI S 20.20, and IEC 61340-5-1 audits, which are critical for manufacturing electronic components for OEMs.

Challenges with ESD PVC Tiles

Despite the initial promise, the ESD PVC tiles quickly proved problematic. The primary issues included:

1. Inconsistent Surface Resistance: The surface resistance of the tiles was unreliable, failing to maintain the required 10^6 to 10^8 ohms across the facility.

2. Import Dependencies: The tiles needed to be imported, leading to supply chain delays and increased costs.

3. Physical Durability: The tiles were prone to damage, particularly at the joints, which needed welding. Any minor floor undulation caused the tiles to peel off or get damaged when trolleys were moved over them.

4. Maintenance Challenges: Replacing damaged tiles was difficult and labor-intensive. The tiles’ low reliability and short lifespan exacerbated these issues.

5. High Overall Costs: The cumulative costs, considering maintenance, replacements,and imports, were very high.

6. Audit Failures: Without reliable ESD flooring, the company struggled to pass the necessary ESD audits, jeopardizing their ability to manufacture for OEMs.

Transition to ESD Epoxy Flooring

Seeking a solution, the company moved to ESD epoxy flooring. However, traditional ESD epoxy solutions, which rely on fiber- based and conductive chemical based technologies, also fell short. They failed to provide uniform conductivity or maintain the required 10^6 to 10^8 ohms resistance uniformly across the expansive half a million square feet manufacturing area.

Introduction of LatChem ESD Epoxy Flooring

Recognizing the need for a more reliable and advanced solution, the company turned to Latern Innovative Engineering Pvt. Ltd. Our LatChem ESD Epoxy Flooring, based on cutting-edge nanotechnology, offered the perfect remedy for their ESD challenges.

The LatChem Solution.

Nanotechnology Advantage: LatChem ESD Epoxy Flooring incorporates nano graphene, silver, silica, graphite, and bentonite. These nanomaterials enhance the flooring’s mechanical properties, durability, and ESD performance.

Key Benefits:

1.Uniform Conductivity: Unlike traditional ESD flooring, LatChem ESD Epoxy Flooring provides uniform surface-to-surface and surface-to-ground resistance, maintaining the crucial 10^6 to 10^8 ohms range across the entire area.

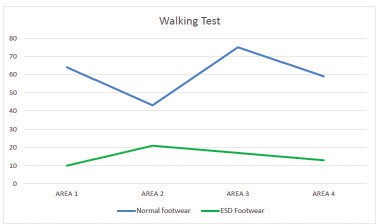

2.Low Voltage Generation: In the walking test, our flooring generates less than 10 volts, significantly below the permissible 100 volts, ensuring superior ESD protection.

3.Durability and Reliability: The nanomaterials used enhance the flooring’s strength and resistance to wear and tear, addressing the physical durability issues faced with PVC tiles.

4.Cost-Effective: With reduced maintenance needs and higher reliability, the overall cost of the flooring solution is significantly lower over its lifespan.

5.Lifetime ESD Guarantee: Our ESD flooring comes with a lifetime guarantee, ensuring that as long as the coating is intact, the ESD properties will be maintained

Implementation and Results

The transition to LatChem ESD Epoxy Flooring was seamless.The company noted immediate improvements in the consistency of the flooring’s ESD properties.The uniform conductivity and low voltage generation were particularly highlighted during subsequent ESD audits, which the company passed with flying colors, thus securing their ability to continue manufacturing for OEMs.

Additionally, the robust nature of the epoxy flooring meant less downtime for maintenance and repairs, further enhancing operational efficiency. The company’s investment in this advanced nanotechnology-based solution paid off through improved reliability, reduced costs, and enhanced ESD protection.

Beyond Flooring: Expanding LatChem’s ESD Solutions

While the LatChem ESD Epoxy Flooring addressed the company’s immediate needs, our comprehensive range of ESD solutions also provided additional benefits:

•ESD Fabrics: Our ESD 100% cotton fabrics replaced imported polyester aprons, offering not only cost benefits but also improved comfort and health benefits for employees.

•ESD Powder Coating Powders: These are used for racks and other equipment, ensuring uniform conductivity and additional ESD protection throughout the facility.

•ESD Plastics and Flexible Packaging: Our ESD rigid plastics and flexible packaging solutions further extend protection to components during storage and transportation, maintaining the integrity of sensitive electronic parts.

Future Prospects and Innovations

As we look to the future, Latern Innovative Engineering Pvt. Ltd. remains committed to pushing the boundaries of what’s possible with nanotechnology in paints and coatings. Our focus is on developing eco-friendly, high- performance solutions that meet the evolving needs of various industries while prioritizing sustainability and innovation.

Emerging Trends:

•Eco-Friendly Paints: We are developing eco-friendly paints that deliver superior performance while minimizing environmental impact. These formulations use sustainable materials and processes, reducing VOC emissions and promoting a healthier environment.

•Direct-to-Metal Paints: We are pioneering the development of direct-to-metal (DTM) paints, which offer excellent adhesion and protection without the need for a primer. These paints simplify the application process, reduce labor costs, and provide superior corrosion resistance.

•Self-Healing and Self-Cleaning Paints: Our research into self- healing and self-cleaning paints aims to revolutionize the industry by extending the lifespan of surfaces and reducing maintenance requirements.

Conclusion

The implementation of LatChem ESD Epoxy Flooring marked a significant milestone for the multi-billion dollar EMS company, overcoming previous challenges with innovative, reliable, and

cost-effective nanotechnology- based solutions. Latern Innovative Engineering Pvt. Ltd. remains committed to pushing the boundaries of nanotechnology in paints and coatings, offering cutting-edge ESD and anticorrosion products that meet the evolving needs of various industries. Our mission is to lead the way in engineering excellence, driving progress and innovation across the globe.

For more information, please visit our website at www.latern. in or contact us via email at kaarthik@latern.in. We invite potential customers to join us on this journey of innovation and excellence. Together, we can drive progress and create a better, more sustainable future.